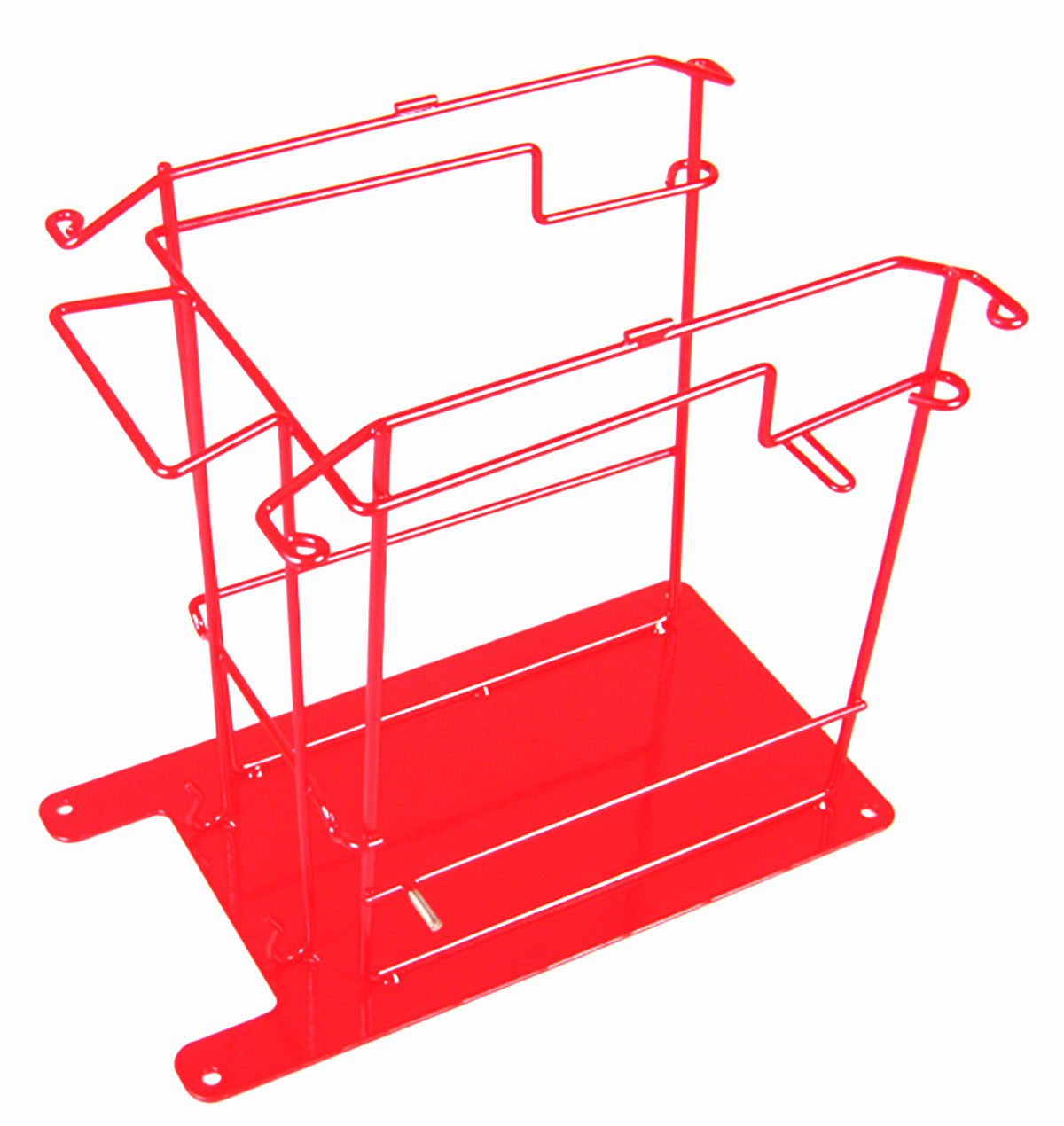

Fluidized Bed Powder Coating applies durable coatings to an entire part or a portion of the part. We are leaders in this unique process, providing cost-viable solutions to meet challenging requirements and demanding timelines that other coating providers cannot match. We take great pride in being a dedicated partner to our customers, deeply understanding their needs and sharing a commitment to their success.

Our processes include epoxy fluidized bed powder coating, nylon fluidized bed powder coating and PVC and polyethylene fluidized bed powder coating.